Author: Jon Lake

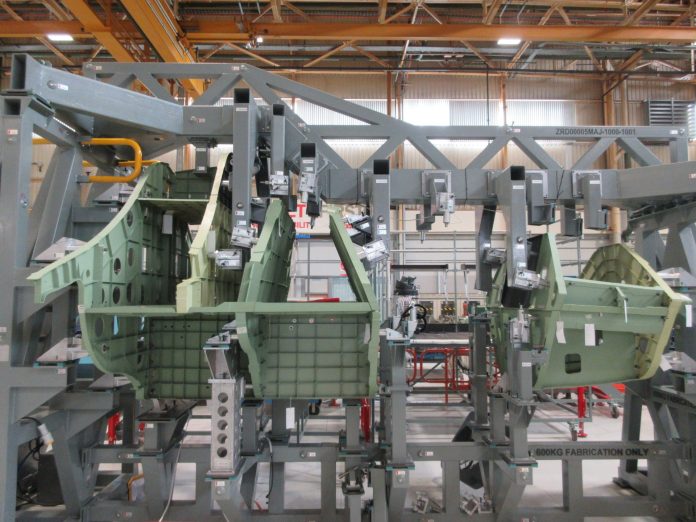

Manufacturing of the main aircraft structure of the UK’s first crewed combat air demonstrator is underway at BAE Systems’ Samlesbury facility, using innovative digital techniques and transformative processes, including advanced manufacturing technologies, virtual simulators and digital rigs. More than half of the aircraft (by weight) is now in build, including all of the major units.

The piloted supersonic test aircraft will serve as a technology demonstrator for the Global Combat Aircraft Programme (GCAP), and will provide data and lessons for the Trinational project, which is being undertaken by the UK, Italy and Japan. The UK version of GCAP is expected to be named Tempest, and will sit at the heart of the FCAS (Future Combat Air System) ‘system of systems’.

The new demonstrator aircraft, which is set to fly within the next three years, will incorporate some stealth compatible features, including an internal weapons bay, but will also pioneer the use of a range of novel technologies. The project will also develop and test the skills, tools, processes and techniques that will be needed to develop Tempest.

Air Commodore Martin Lowe, Future Combat Air Systems Programme Director for the UK Ministry of Defence, said that: “The demonstrator is helping us understand more about the advanced technology that is required to deliver a sixth-generation fighter jet. The progress we have made together – MOD and industry – in such a short space of time has been remarkable. A large part of this is down to a new generation of engineering specialists who are using innovative manufacturing solutions to deliver this demonstrator aircraft.” Lowe admits to having had a poster of the BAe EAP technology demonstrator on his wall when he was a youngster, and hopes that today’s combat air demonstrator will inspire today’s aviation mad youngsters, and that it will provide a cadre of ‘SQEP’ (suitably qualified and experienced personnel) for the GCAP effort.

Paul Wilde, Head of Tempest, at BAE Systems, said: “The flying technology demonstrator is a vital initiative for developing national skills and advanced technology, ensuring the UK remains a world leader in the design, production, test and certification of combat aircraft. Partnering with around 100 UK suppliers, including our Team Tempest partners, we’re combining engineering expertise with innovative methods to enhance and refresh crucial industrial skills which is so important as we get ready to deliver the Tempest programme.

BAE Systems and its supply chain partners are using additive manufacturing processes and technologies, including 3D printing, to develop many of the vital structural parts of the aircraft. The use of Hot Isostatic Press (HIP) technology uses extreme heat and pressure to create a solid metal part in any required shape, in less time and at reduced cost compared to using traditional forgings, and creates less material waste.

The UK Government first announced the flying combat air demonstrator project in July 2022, and test pilots from BAE Systems, Rolls-Royce and the Royal Air Force (RAF) have now ‘flown’ more than 215 hours in a bespoke simulator, providing crucial evidence to support the design of the aircraft and enabling test pilots to become familiar with flying the aircraft before its first ‘live’ flight.

Paul Wilde says that: “The demonstrator is a ground-breaking initiative which will showcase the best of British engineering, supporting apprentices and graduates who learn from our best engineers, keeping the UK at the forefront of defence and aerospace.”